Digital technology is adding new dimensions to oral care. Just ask Daniel Givan, D.M.D., Ph.D., professor of restorative sciences in the School of Dentistry. “We’ve had more changes in dental technology in the last five years than in the previous 100 years,” he says. And those innovations are helping dentists, orthodontists, oral surgeons, and others tailor care and treatment to fit each patient’s unique needs. Here are five ways 3-D is shaping smiles:

Better impressions: Anyone who has had braces, crowns, and bridges can recall the wet, gummy, messy discomfort of holding plaster in their mouths for several minutes to make impressions. Now intraoral or optical impression scanners can capture digital images of a patient’s teeth using light projected from hand-held wands. “The device takes a lot of pictures, which are combined to make a virtual 3-D model,” explains Shirin Khoynezhad, D.D.S., D.M.Sc., assistant professor of prosthodontics. Dental professionals can manipulate the virtual model to visualize the teeth and develop plans for restoring them. Then they send the electronic impression to a laboratory that fabricates items such as crowns, bridges, inlays, or mouth guards. The technology solves another problem with conventional impressions. Because plaster can change in size as it sets, dentists often have had to adjust finished crowns and bridges to make them fit properly, Khoynezhad says.

Speedy solutions: Patients once waited weeks to have crowns and other prosthetics made or repaired. Now computer-assisted design (CAD) and computer-assisted manufacturing (CAM) make it possible for patients to receive their customized prosthetics in days—sometimes hours. Dentists take digital scans of a patient’s teeth and upload them to a laboratory, where a CAD machine engineers the one-of-a-kind dental appliance. Then, using a CAM milling machine, a technician creates the final prosthetic out of materials like ceramics and resin composites.

Printed prosthetics: Some custom prosthetics are now produced on 3-D printers, which use resins to form the needed part layer by layer. “3-D printing has exploded,” Givan says. “We’re now producing temporary crowns and bridges. Some are more experimental at this time, but this technology is here to stay.”

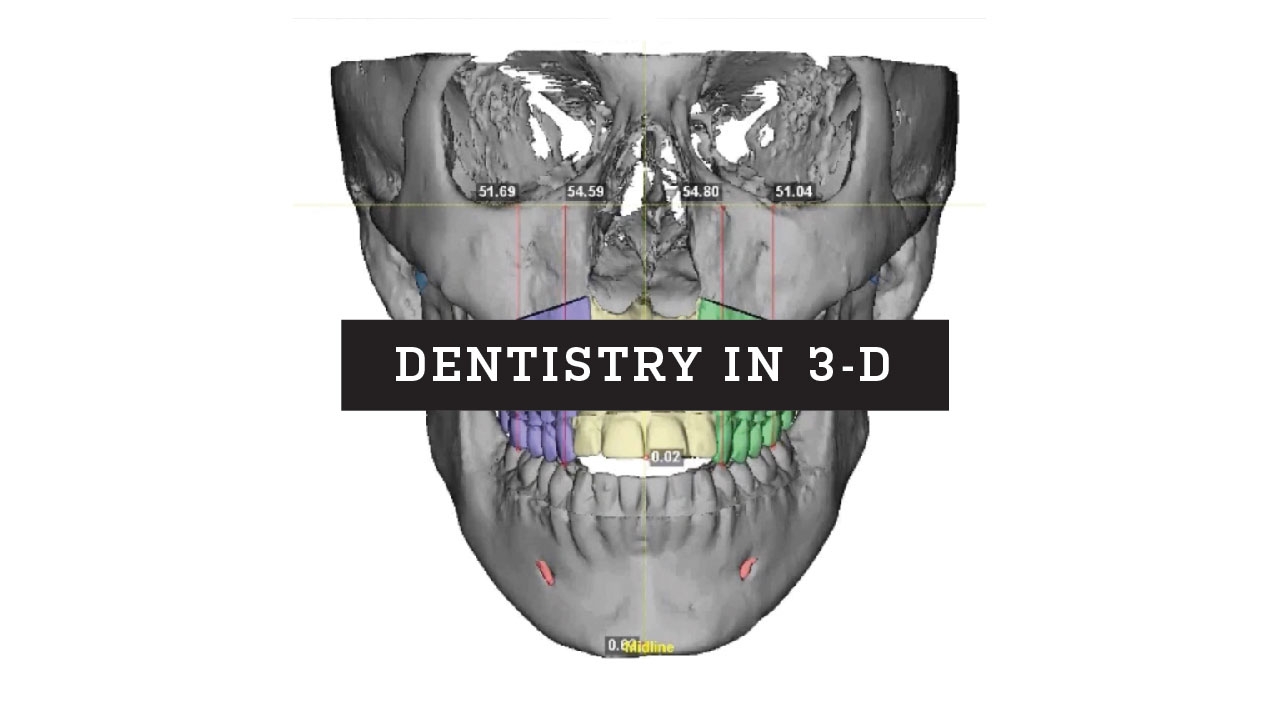

3-D scans (at top) guided jaw reconstruction for Valerie Accetta, helping her teach and sing again.

Jaw adjustments: A jaw misalignment affects the ability to chew or talk, plus it can be painful. Digital jaw-tracking systems use sensors to observe, record, and measure jaw movements, up and down and side to side, in relation to the rest of the skull. When Valerie Accetta, M.F.A., UAB’s head of musical theatre, needed reconstructive surgery to repair deterioration of her jaw, the team that successfully treated her used jaw-tracking technology as part of their surgical preparations, says Chung H. Kau, D.D.S., Ph.D., chair of orthodontics. “The jaw tracking was critical to our success since it allowed us to study the relationship of Valerie’s jaw and muscles in real-time movement,” Kau says. “From there, we were able to digitally plan exactly where the customized joints would fit in her jaw, a process that helps all involved be as precise as possible before surgery begins.”

Surgery prep: Kau and Patrick Louis, D.D.S., M.D., professor of oral and maxillofacial surgery, collaborated on Accetta’s case using virtual surgical planning software. The technology enabled them to confer and examine 3-D images of Accetta’s jaw together, and to strategize, simulate jaw positioning, and develop the best plan before the operation—all online. Today Accetta is singing and teaching again.

Look for 3-D innovations to bring smiles to more dental patients—and give dentists greater precision and efficiency—Givan says. “The technology is a help,” he says, “but it still requires well-trained individuals to ask the right questions and to understand how to apply these tools appropriately to each patient.”